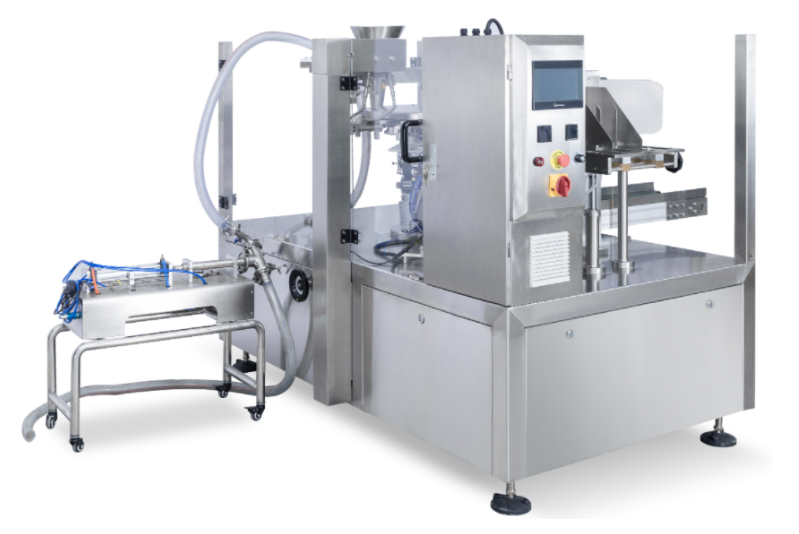

XLY 8200 machine with Liquid pump system Packing System list

Features

A. Rapid change of the specifications of the bag, bag width can be automatically adjusted by one button.

B. Single shaft and the CAM design: packing speed faster; more stable operation ; maintenance easier and reduce defective rate.

C. Modular heating, temperature control more accurate, heating fault have alarm prompt.

D. Advanced design idea, reduce the material loss, ensure the stability of equipment operation, extend the operating life of the equipment.

E. Simple and convenient operation, adopts the advanced PLC + POD (touch screen) electric control system and man-machine interface.

F. Machine have wide packaging range , it can packaging : liquid, paste, granule, powder, solid various bagging materials only. According to the different material with different metering device.

G. Machine use preformed bags & packaging design is perfect & good sealing quality to improve the quality and grade of the product.

Purpose of the machine

Bag given packing machine adopts preformed bags, packaging design and beautiful, good sealing quality, tend to be more perfect packaging technology, perfect quality guarantee high and stable production, keep the machine durable and stable operation, waterproof system make cleaning cleaning more convenient. Packaging process without manual operation, effectively improves the production efficiency, for your company to save the labor cost and management cost, greatly reduce the cost.

Specification

Item | Content |

Machine position | Eight position working |

Pouch material | Laminated film\PP\PE etc. |

Pouch pattern | Flat pouch, Stand-up pouch with or without zipper |

Packing speed | *20~60 bags/min, depend on the measuring equipment, materials, product’s weight & packing film’ material. |

Accuracy | *≤±1%, depending on the measuring equipment & materials. |

Bag size | (L)100-300mm (W) 70-200mm |

Filling Volume | 10-1000g |

Bag type | Preformed bag: Spout bag, Zipper bag, Stand-up pouch, 3/4-side-seal flat pouch, four edge-sealing bag, special bag etc. |

Pouch thickness | |

Air consumption | 0.6m3/min(supply by user) |

Power | 3KW 3P 380V 50/60Hz |

Dimension | (L)1900 * (W)1570 * (H)1420mm |

Weight of machine | 1300kgs |

Work flow | Giving bag→ Coding→ Opening→ Filling 1→ Filling 2→ Auxiliary→ Exhaust→Heat sealing→Forming and output product. |

2. Liquid/paste type: Gel, liquid alcohol cocktails, liquid detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste | |

Main standard parts | 1. Code printer 2. PLC control system 3. Bag opening device 4. Vibration device 5. Cylinder 6. Electromagnetic valve 7. Temperature controller 8. Vacuum pump 9. Inverter 10. Output system |

Contact: Candy

Phone: +86 18978411594

Tel: +86 18978411594

Email: Info@xinleiyuanpacking.com

Add: Unit address: Room A02, Building 14, Wanyang Innovation Park, Xiaotang Industrial Avenue, Shishan Town, Nanhai District, Foshan City